current information

August 2020

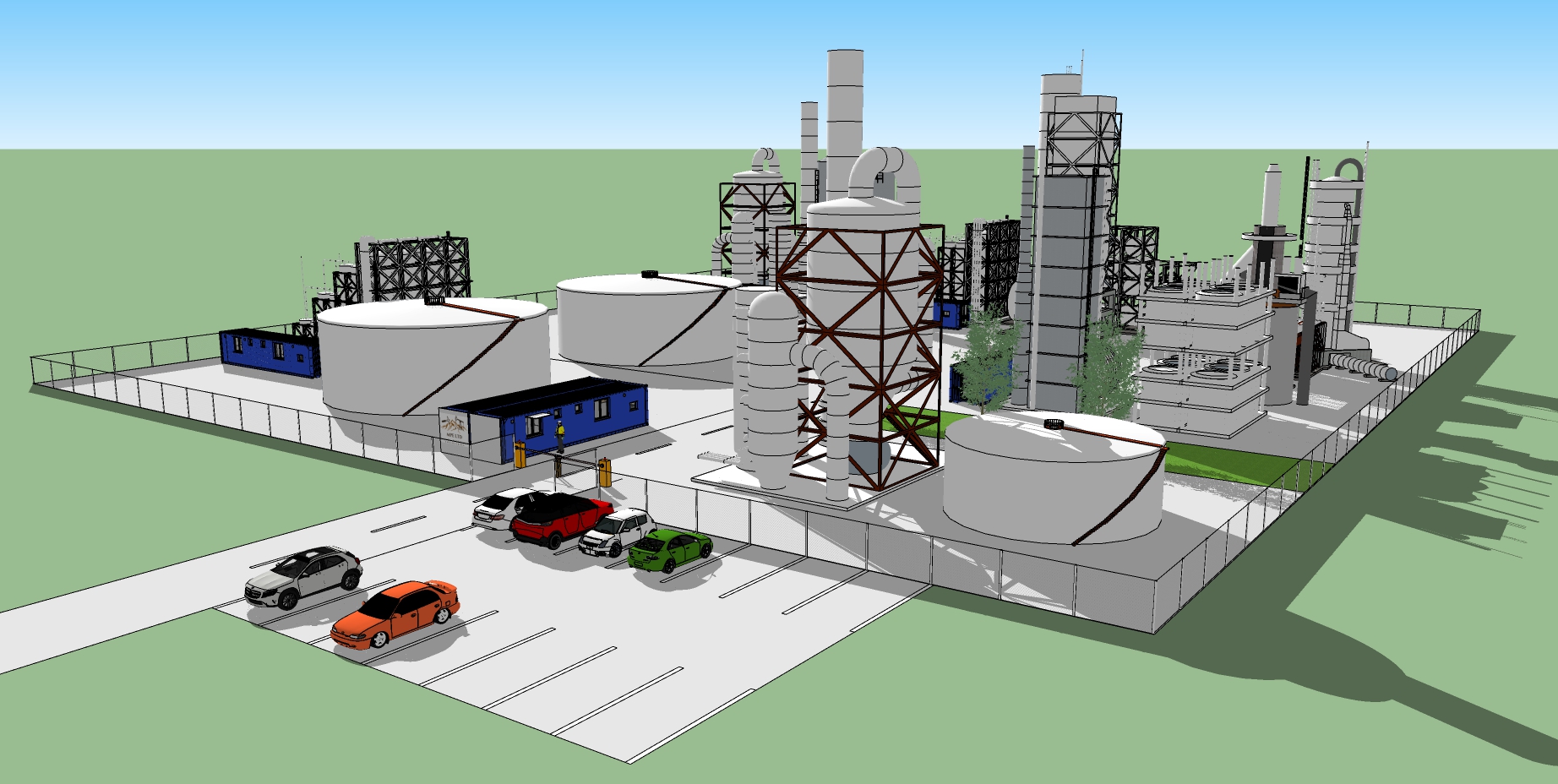

IFO Desulfurization

Due to the current market demand for the desulfurization of marine fuels, the ECO-DESULFOX S-5000/500 was developed.

November 2019

Drinking water systems for Papua New Guinea

As part of an environmental assessment in Madang Province, Papua New Guinea, heavy metals and toxins were discovered in drinking water. PITT GmbH was awarded the contract for planning of special solar-powered drinking water systems.

May 2018

First PITT-TPS in Russia.

First Three Phase Separator in Russia has been installed in a steel mill. The task is to remove both free oils and heavy particles out of process water.

June 2017

We've movedFrom the 1st of June 2017 you will find us in the new Technology-Center in Poststraße 68, 44809 Bochum, close to the A40.

June 2016

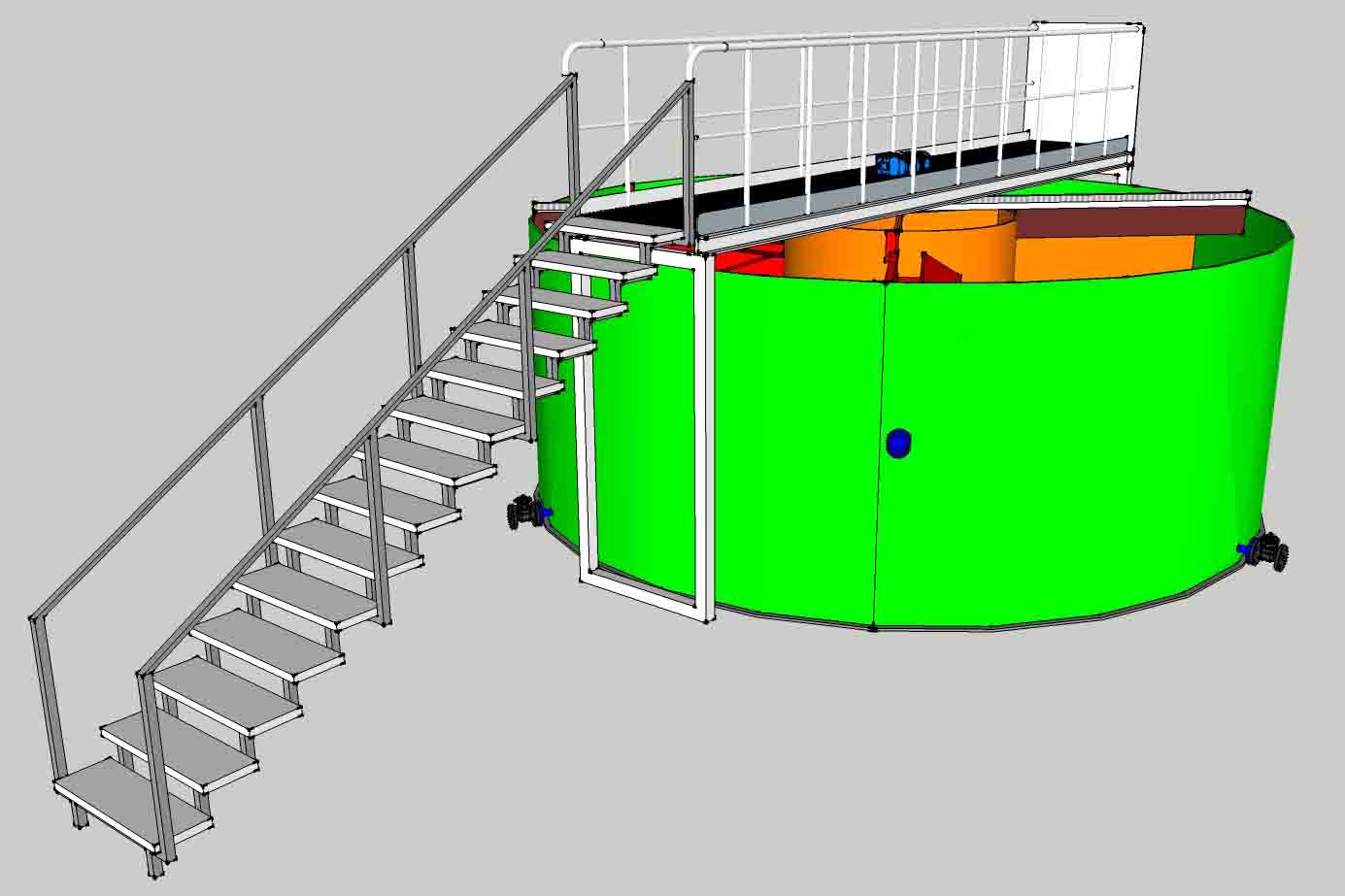

The new generation of DAF-3.000..30.000 is available.

The advanced technology replaces the series DAF 30..120. Not only the color has changed. The process flow is enhanced by numerous innovations. Inform yourself!

July 2014

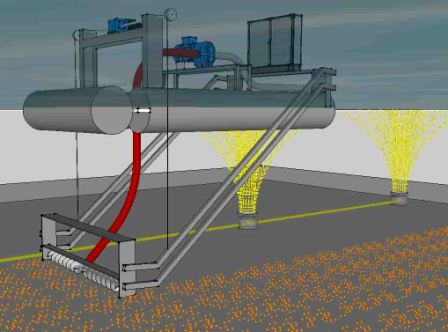

Innovative pond water regeneration PITT-REPAIR for sustainable and certified fish farming

Taking into account of GLOBALG.A.P. requirements the new technology PITT-REPAIR (rearing pond air) regenerated rearing ponds for Pangasius and other freshwater fishes. PITT-REPAIR is an effective combination of oxygen injection and pond bottom cleaning. Inform yourself!

July 2013

Foundation of PITT agency in ShanghaiWith immediate effect PITT GmbH is represented by FIRST ENVIRONMENT PERFORMANCE GMBH in China. The agency starts with order of large-scale flotation DAF 300/3-C2 for waste water of dyeing industry.

September 2012

New standard procedure for food industry

The new modular technology DAF-SBR, a combination of chemical and biological water treatment, delighting our customers. A meat processing plant and a dairy farm in Romania are equipped with the new technology.

January 2012

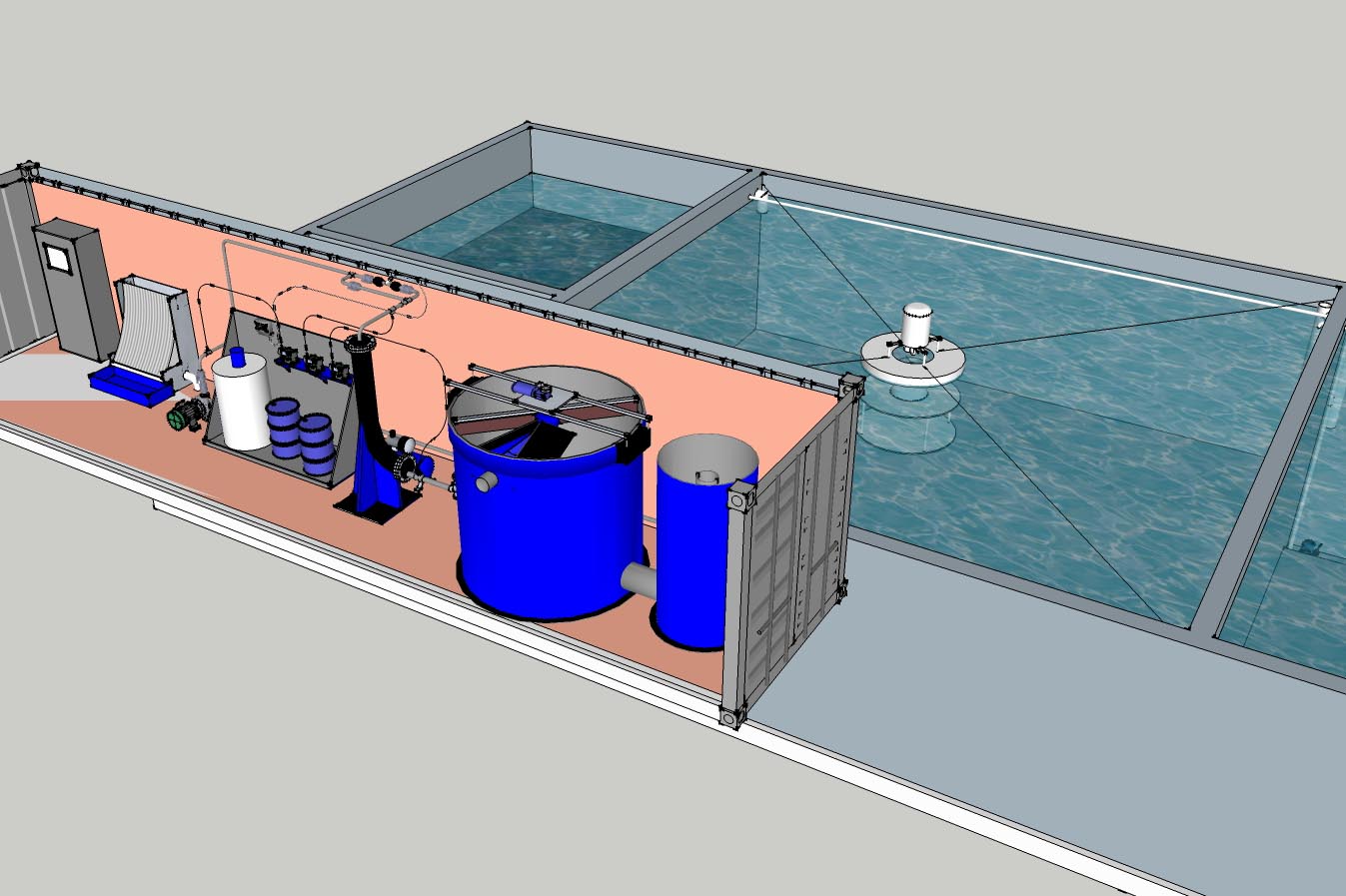

New in product range: Flotation plant in modular design

Modular DAF plants with a capacity of 40 to 200 m³ / h are available now. Costs and time for assembly are radically reduced.

February 2011

PITT Newsletter

Find out about our current activities and request the newsletter by e-mail.

August 2010

PITT Agency in Russia.With immediate effect PITT GmbH is represented by OOO EKOTECH-AQUA. The experts for waste water engineering present the product range of PITT GmbH on the Russian market. Click here for contact details

July 2010

First PITT flotation in Romania.

A unit of our DAF 100-1280-series (30 m²/h) has been installed by our Romanian partner ATB. Waste water from a dye works facility in the automotive industry is analyzed and chemically treated prior discharging into sewer.

January 2010

First AEROS in Ukraine.

The first AEROS in Ukraine has been installed. With our AEROS technology, it is possible to clean and recycle washing water from a manual car wash installation up to 100 per cent.

August 2009

Our PTT DAF-technology “aquaflow” will be marketed worldwide in combination with the proven “Dekanter”, a technology of our partner GEA.

Special leaflets are available on [digestate treatment in biogas plants] and [waste water treatment in refineries].

February 2009

Our high-performance separator TPS is launched.

The innovative 3-phase-separator-technology enables concurrent separation of oil and suspended solids from process water in one passage. [more...]

GEA Centrifugal technology

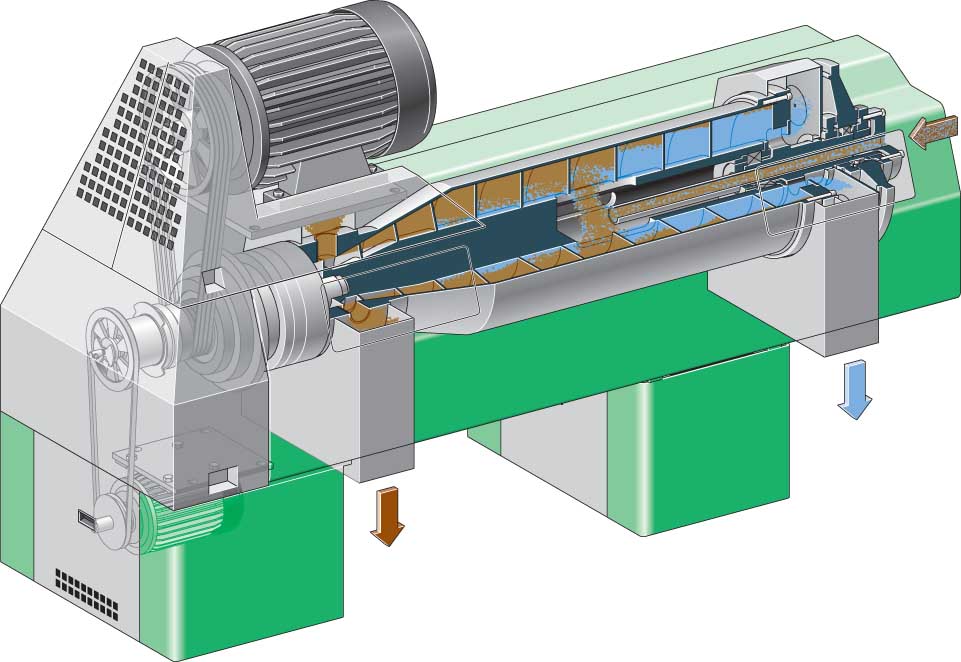

Decanters

Decanters, also called solid-wall scroll centrifuges, operate with a horizontal axis of rotation and are used in waste water treatment for thickening sewage sludge and dewatering. They function on the principle of tube centrifuges but are equipped with a scroll rotating at a slightly different speed than the bowl, enabling them to continuously discharge the separated solids out of the centrifuge bowl. This makes possible a high separation efficiency in a small space.Decanter from GEA Westfalia Separator are robust centrifuges and consequently the long-term, quality response to many issues in the treatment of industrial waste waters. A self-cleaning separator can be installed downstream for polishing the liquid phases.

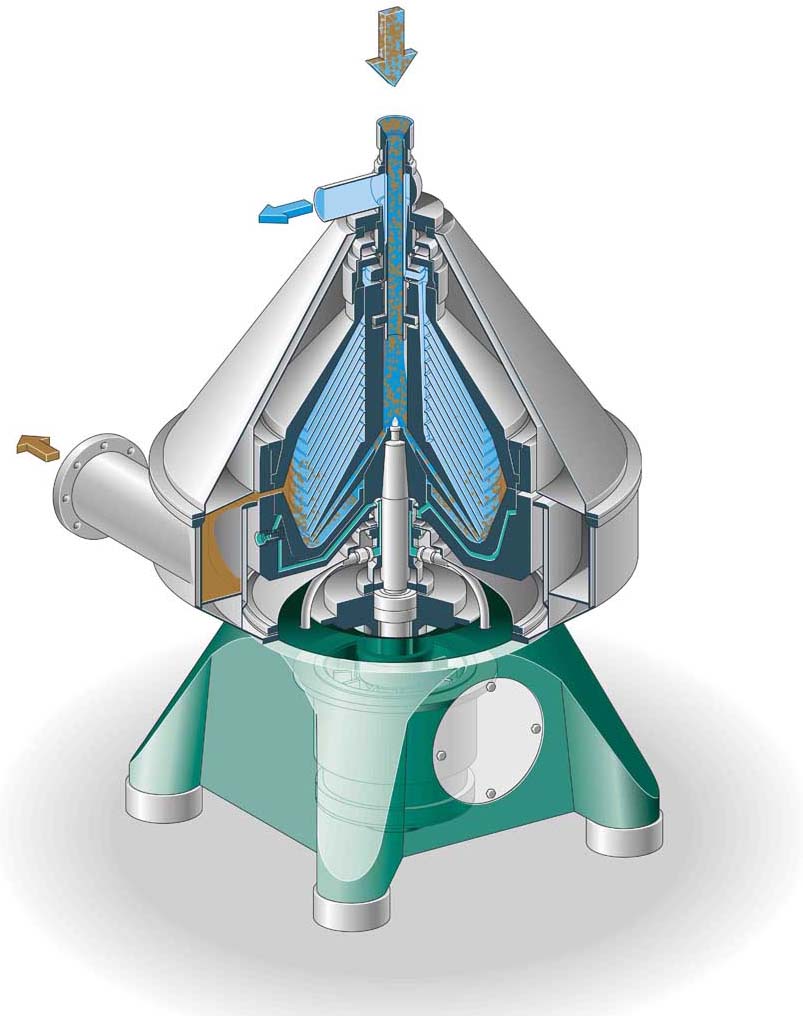

Separators

Separators are able to handle clarifying as well as separating duties, and are used wherever large volumes of liquids with a relatively low solid content have to be treated. The principle and method of operation are roughly equivalent to those of a washing machine, however they are much more complicated and feature sophisticated modifications which can be adjusted to meet the requirements of the specific areas of application. Separators operate with a vertical rotation axis. The heart of the units are disc stacks that are inclined in relation to the vertical axis of operation and have very narrow gaps. As a result of the interaction between rotation and the disc stack, the solids are separated from the liquid to be purified and, depending on the particular type, are ejected through nozzles or by a sliding valve. Depending on the particular area of application, separators are equipped with a concentrate recycling facility or a washing facility. Separators from GEA Westfalia Separator are designed especially for extremely delicate tasks and produce a clear phase separation, high levels of efficiency and an extremely sharp cut.

For Combination of DAF- and Centrifugal technologies specific brochures are available:

Waste water treatment in biogas plants [Brochure "Biogas" download]

Waste water treatment in refineries [Brochure "Refinery" download]