current information

August 2020

IFO Desulfurization

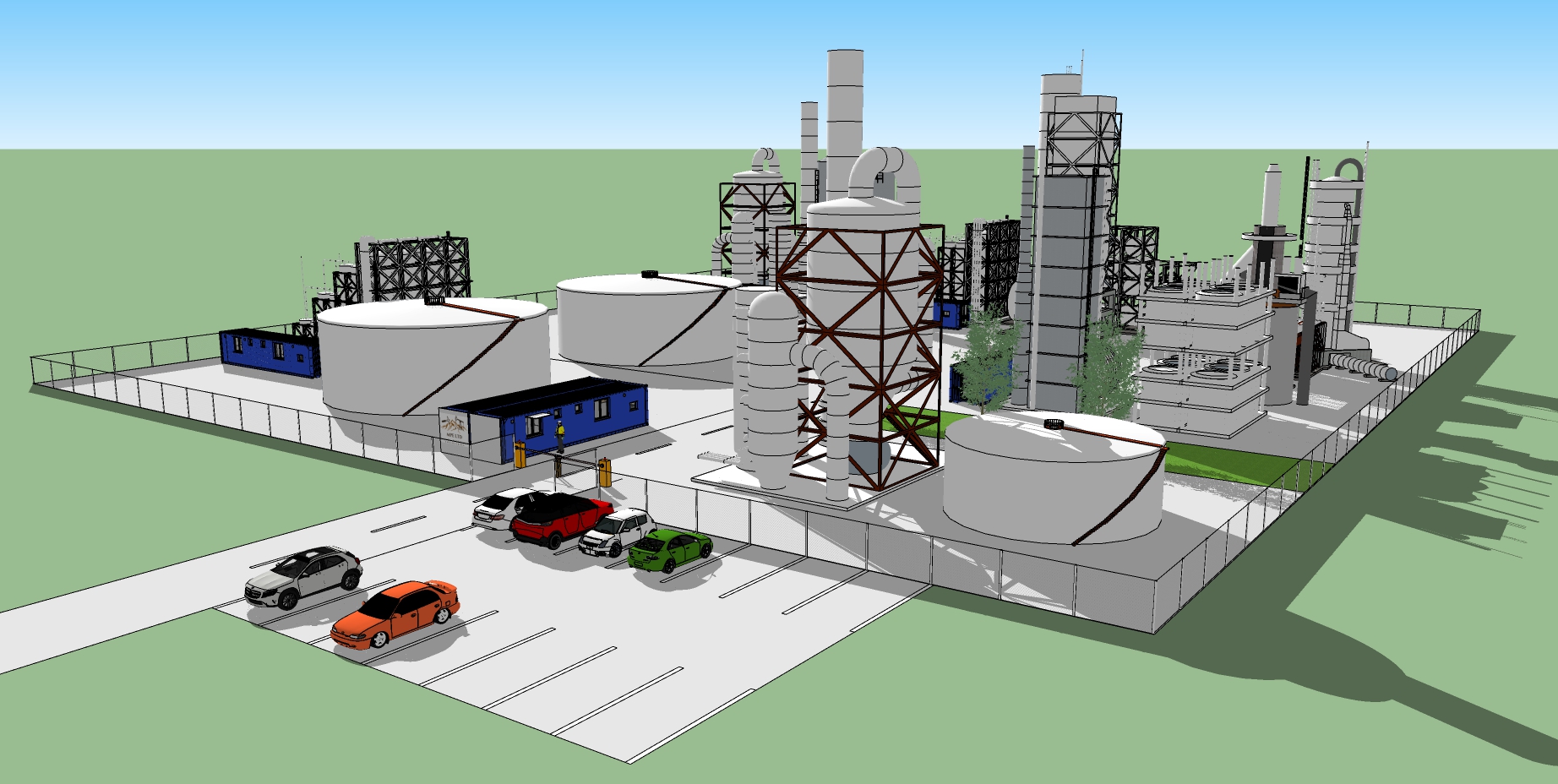

Due to the current market demand for the desulfurization of marine fuels, the ECO-DESULFOX S-5000/500 was developed.

November 2019

Drinking water systems for Papua New Guinea

As part of an environmental assessment in Madang Province, Papua New Guinea, heavy metals and toxins were discovered in drinking water. PITT GmbH was awarded the contract for planning of special solar-powered drinking water systems.

May 2018

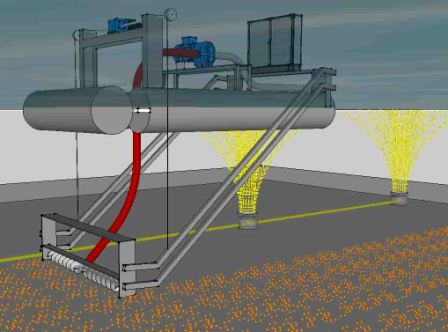

First PITT-TPS in Russia.

First Three Phase Separator in Russia has been installed in a steel mill. The task is to remove both free oils and heavy particles out of process water.

June 2017

We've movedFrom the 1st of June 2017 you will find us in the new Technology-Center in Poststraße 68, 44809 Bochum, close to the A40.

June 2016

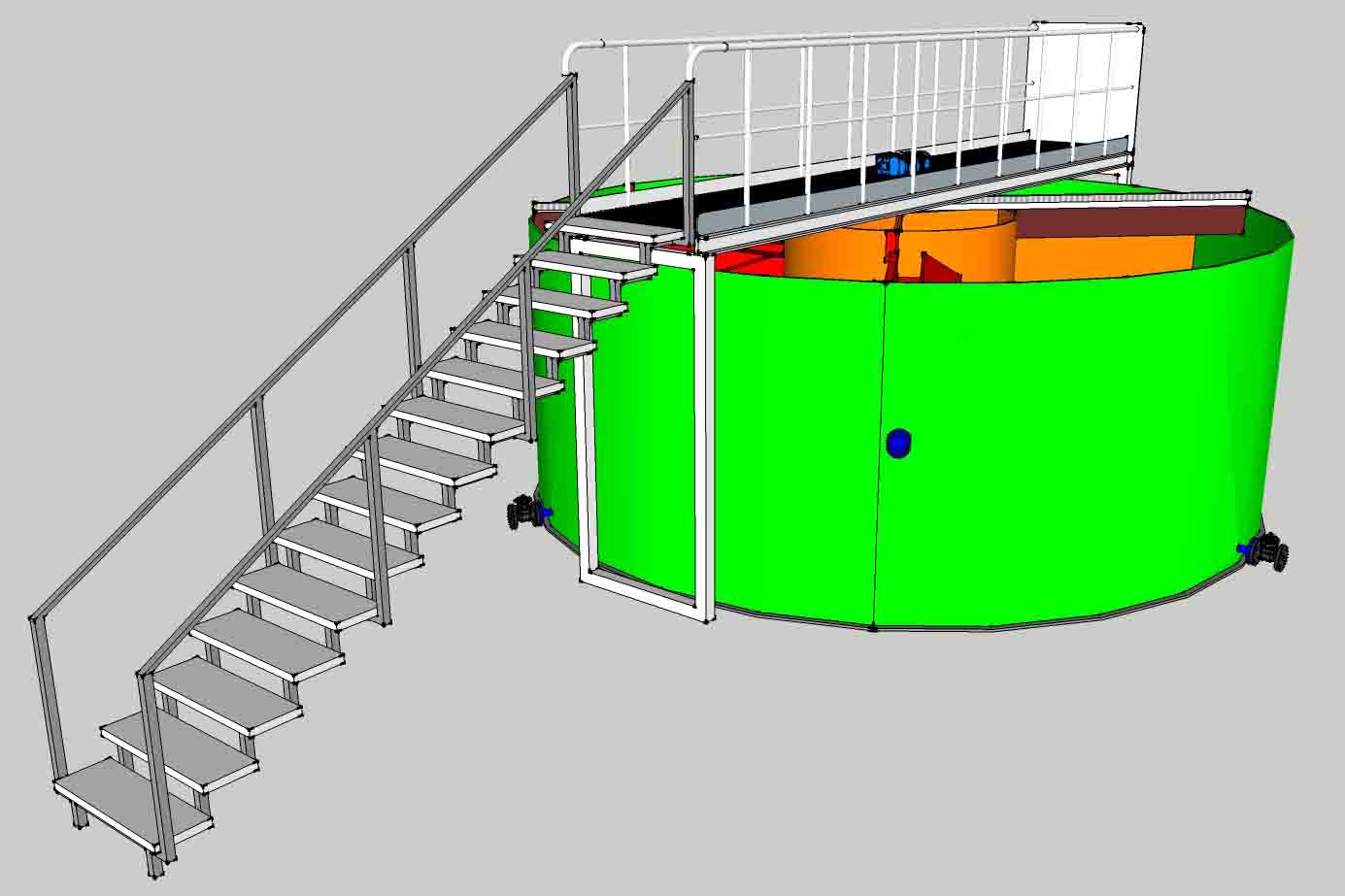

The new generation of DAF-3.000..30.000 is available.

The advanced technology replaces the series DAF 30..120. Not only the color has changed. The process flow is enhanced by numerous innovations. Inform yourself!

July 2014

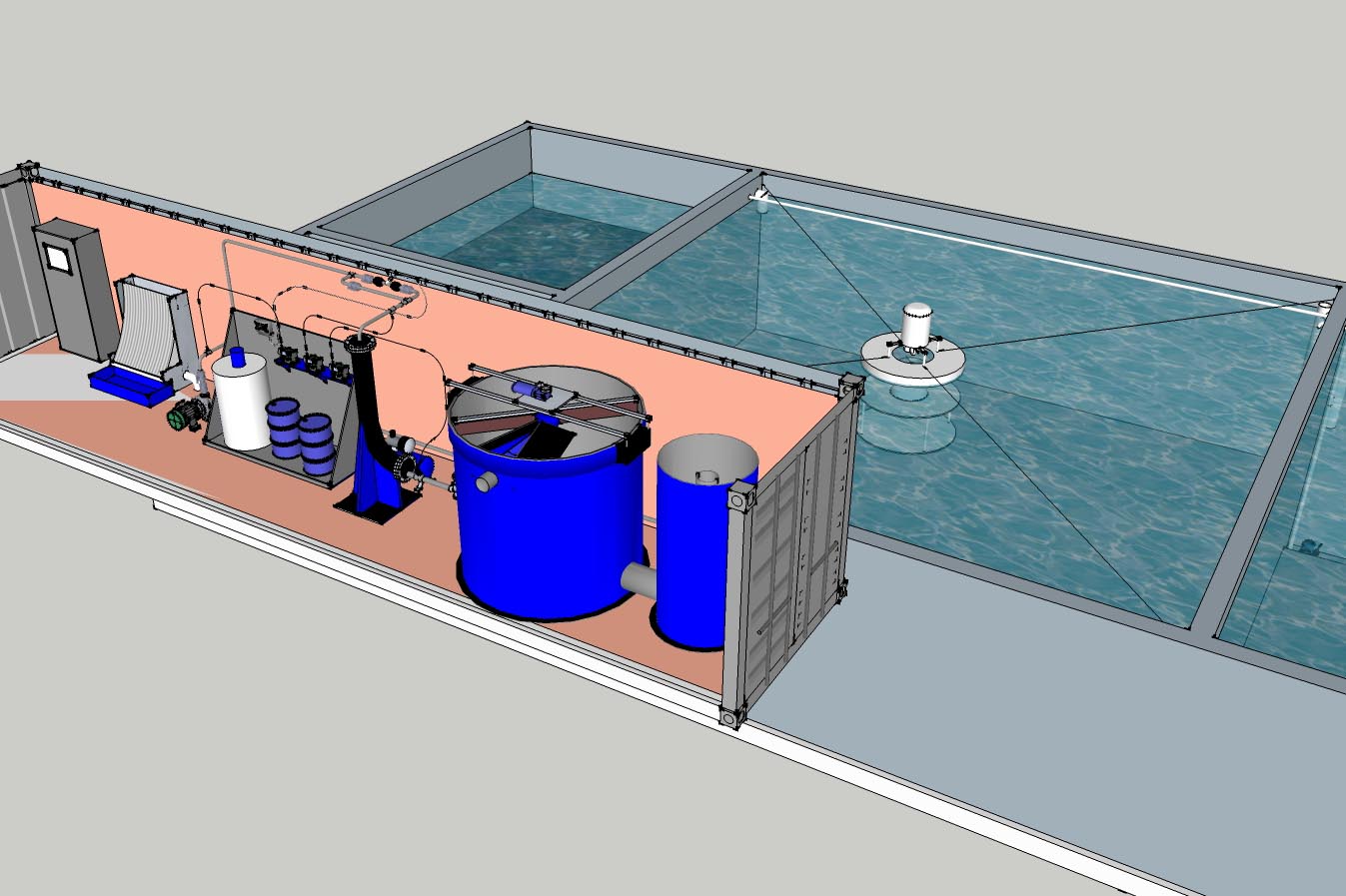

Innovative pond water regeneration PITT-REPAIR for sustainable and certified fish farming

Taking into account of GLOBALG.A.P. requirements the new technology PITT-REPAIR (rearing pond air) regenerated rearing ponds for Pangasius and other freshwater fishes. PITT-REPAIR is an effective combination of oxygen injection and pond bottom cleaning. Inform yourself!

July 2013

Foundation of PITT agency in ShanghaiWith immediate effect PITT GmbH is represented by FIRST ENVIRONMENT PERFORMANCE GMBH in China. The agency starts with order of large-scale flotation DAF 300/3-C2 for waste water of dyeing industry.

September 2012

New standard procedure for food industry

The new modular technology DAF-SBR, a combination of chemical and biological water treatment, delighting our customers. A meat processing plant and a dairy farm in Romania are equipped with the new technology.

January 2012

New in product range: Flotation plant in modular design

Modular DAF plants with a capacity of 40 to 200 m³ / h are available now. Costs and time for assembly are radically reduced.

February 2011

PITT Newsletter

Find out about our current activities and request the newsletter by e-mail.

August 2010

PITT Agency in Russia.With immediate effect PITT GmbH is represented by OOO EKOTECH-AQUA. The experts for waste water engineering present the product range of PITT GmbH on the Russian market. Click here for contact details

July 2010

First PITT flotation in Romania.

A unit of our DAF 100-1280-series (30 m²/h) has been installed by our Romanian partner ATB. Waste water from a dye works facility in the automotive industry is analyzed and chemically treated prior discharging into sewer.

January 2010

First AEROS in Ukraine.

The first AEROS in Ukraine has been installed. With our AEROS technology, it is possible to clean and recycle washing water from a manual car wash installation up to 100 per cent.

August 2009

Our PTT DAF-technology “aquaflow” will be marketed worldwide in combination with the proven “Dekanter”, a technology of our partner GEA.

Special leaflets are available on [digestate treatment in biogas plants] and [waste water treatment in refineries].

February 2009

Our high-performance separator TPS is launched.

The innovative 3-phase-separator-technology enables concurrent separation of oil and suspended solids from process water in one passage. [more...]

The innovative water purification for car wash

The product

The AEROS technology is a europewide renowned system employed for permanent production of dissolved air in waste water.

The AEROS uses an innovative and unique way in producing micro bubbles in the water and effectively saturating the water with air.

High quality and long lasting materials insure a reliable use with low maintenance needs. Due to a modular built up a multiple use is possible. The AEROS can be used as a stand alone version to eliminate bad odours in wash points as well as a main module in big DAF plants (dissolved air flotation).

Developing the AEROS it was our intent to insure an ecological and economical way of use. For example, when using the AEROS in wash points up to 100. 000 car washes per year the energy need is as low as 900 up to 1.100 Watt.

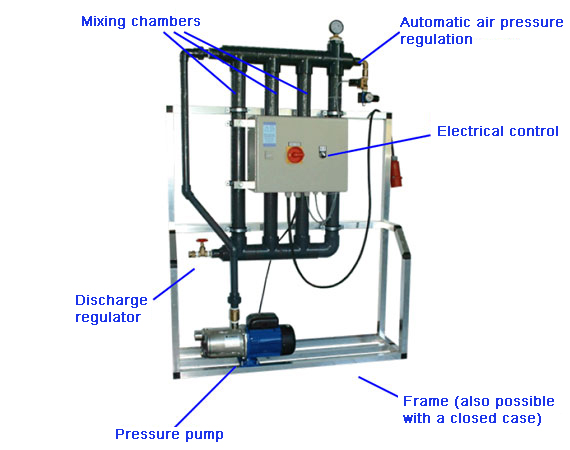

Subassemblies of AEROS

The procedure

The waste water first flows to the first sludge trap where the most bigger size mud is sedimented.

Then the water flows further to the second sludge trap (if needed), where more smaller sized mud is seperated by sedimentation.

After this the water comes to the recycling tank where an under water pump brings the water to the clear water tank. From here the water for the washing process is pumped to the wash portal by a pressure pump.

The AEROS system takes also water out of the clear water tank and saturates this water with air.

Then this saturated water is brought to the recycling tank by a certain jet system in a special way that guarantees long lasting bubbles. Due to the depressuration while taking the water to the tank, tiny microbubbles with a diameter of 30 to 60 µm develop.

All small pieces of mud or other substances in the water adhere to the micro bubbles and float up to the surface where a bubble carpet developes.

In the bottom section of the recycling tank develops a clear water zone from which the water for the washing process is pumped to the upper take off tank. This bubble carpet flows over the recycling tank into the drain canalisation when additional water is brought to the system. Thus the tiny particels like mud or oil are effectively brought out of the system.

Other applications

Due to the modular construction a big variety of applications is possible. Very often the system is used in wash points where all advantages of the AEROS system can unfold effectively as reducing bacteria, eliminating bad odours, floating out the tiny substances.

Further more the AEROS system can be used as a main module for a big “DAF” (dissolved air flotation).

In this case two kinds of constructions can occur:

- Using the main stream process the whole amount of waste water is pumped across the AEROS system. Using this process chemical flocculant can be added to crack off emulsions.

- Using the bypass process the AEROS system is just used to produce the micro bubbles. Hereby a defined part of the water with the produced micro bubbles is mixed with the main stream.

The AEROS has a capacity from 3 m³/h to 40 m³/h. To germinate the recyclingwater it can also be combined with the UV-Cleaner. Please ask our experts.